Key Operational Challenges in TMR Feed Management

Inconsistent Rations & High Waste

Manual mixing often leads to over 5% formula deviation and 5–10% feed waste due to sorting and leftovers, directly reducing milk yield and increasing cost.

Paper & Memory Create Gaps

Paper-based, people-dependent work has no standard, no trace, and no verification — so quality suffers when key staff are away.

No Data for Optimization

Without accurate tracking, farmers lack insight into feed ROI, cost per liter, wastage patterns, and cannot link feeding actions to milk output or health changes.

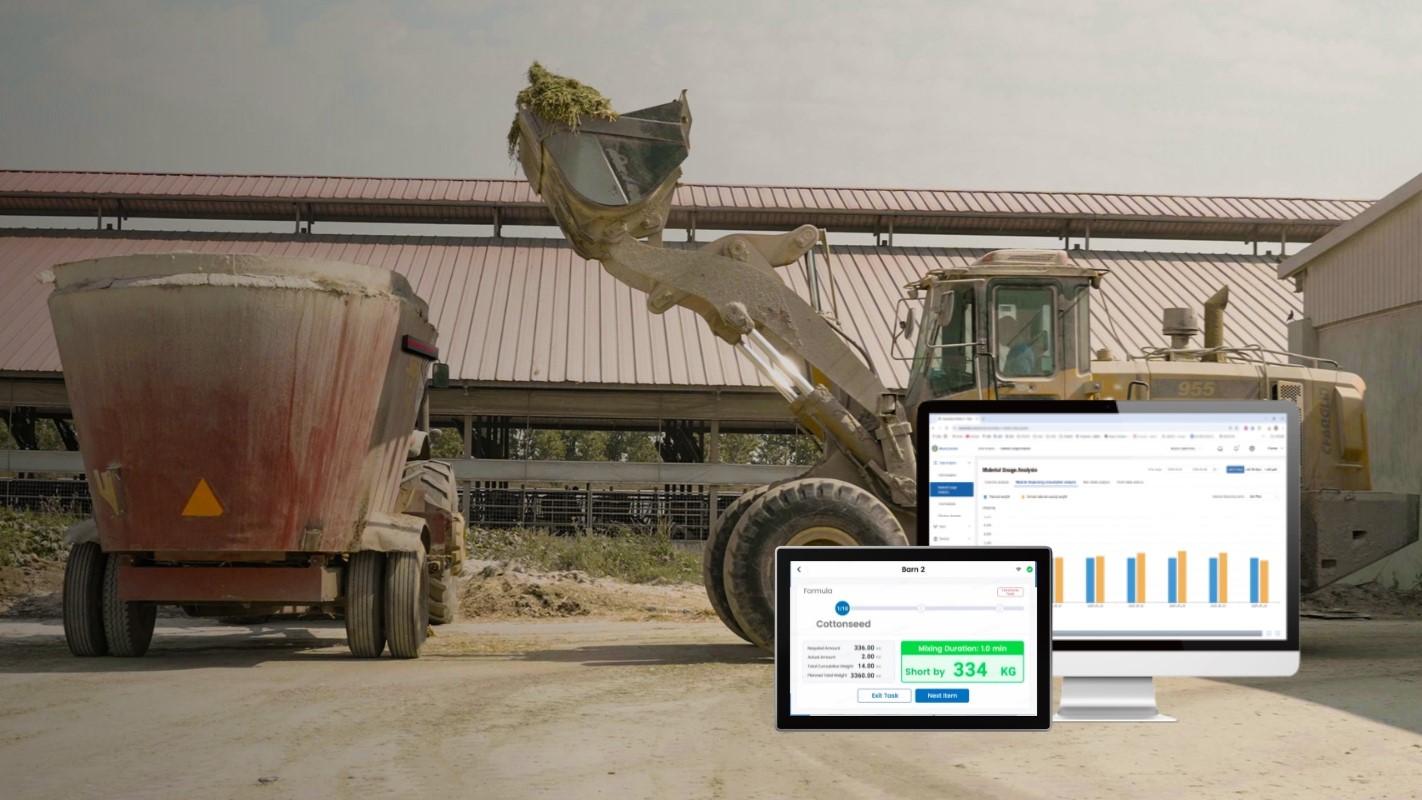

Meet Sveaverken FeedLogger

Sveaverken FeedLogger brings TMR feeding into the digital age with clear records, live visibility, and smart automation. Go fully online: set TMR feed formulas, assign tasks, track progress, and fine-tune strategies — all from your laptop. It gives you full real-time oversight of TMR — from records and photos to alerts and reports — with complete traceability of formulas, quantities, timing, and operators. That means less guesswork, more time saved, and higher efficiency.

How much could you save with FeedLogger?

- Feed waste cut by 5–10%

- Milk/DMI increased by 2–5%

- Labour reduced by 1–2 hours daily

Daily Dose Wizard

Calibrates every TMR batch to exact dry-matter targets and ingredient costs. Start each day with precise on-screen plans and clear prompts — say goodbye to paperwork!

Cab Companion

In-cab prompts guide operators through each step. Instant feedback confirms weight tolerances and flags any variance, ensuring consistent, error-free mixes.

Instant Insights

See batch weights, leftovers, and milk yields side by side. Trend charts, KPI alerts, and inventory forecasts highlight cost leaks, track ROI, and help you fine-tune feeding strategies in minutes.

Farm Smart Ecosystem

With FeedLogger, Nimbo feed pusher uses smart cameras to scan and track leftovers, showing real-time reports in MooConnect so you always know what’s left and needed — cutting waste and improving feed management.

And there’s more: when the mixer wagon starts, FeedLogger automatically reschedules Nimbo’s feed pushing time to avoid equipment conflicts, keeping your mixer and feed pusher working in sync.

FeedLogger Pro: Auto Silo Control

Still opening silos by hand? Time to go Pro. FeedLogger Pro connects directly to your concentrate silos, automatically opening and closing them to dispense exactly what the ration requires — no manual handling needed.

With a single tap on the in-cab display, the command is sent to the FeedLogger Pro control panel, which remotely operates the silo tower to deliver the precise amount of feed. Every kilogram is tracked live on screen, and once the target is reached, dispensing stops automatically.

How to Automate Cattle Feeding with Sveaverken FeedLogger

How to Automate Cattle Feeding with Sveaverken FeedLogger

- Create Your Recipe

Enter each feed type and create a recipe - Set Cattle Groups

Define headcount and groups. - Create Feeding Plans

Assign groups to recipes, devices, and drivers. - Schedule Feeding

Choose time and frequency for tasks. - Execute the Plan

FeedLogger records feed info & analyses it automatically.