- Herd Management

- Precision Farming

- Lawn Care

- Commercial Cleaning

Sveaverken Nimbo X

Sveaverken Glide Flo

Sveaverken Nimbo

Sveaverken MooCollar Bree

Sveaverken Pocket Mapper

Sveaverken Brush

Sveaverken F200 Max Auto Steer System

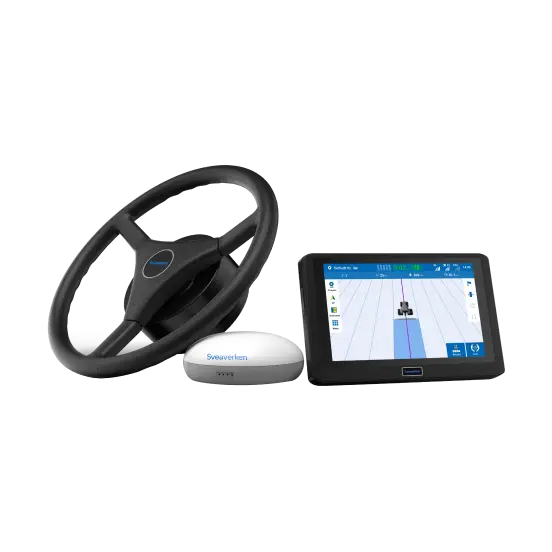

Sveaverken F200 Auto Steer System

Sveaverken F100C RTS Auto Steer System

Sveaverken F100 Auto Steer System

Sveaverken F100G Tractor Guidance System

Sveaverken F100H Steer Ready Auto Steer System

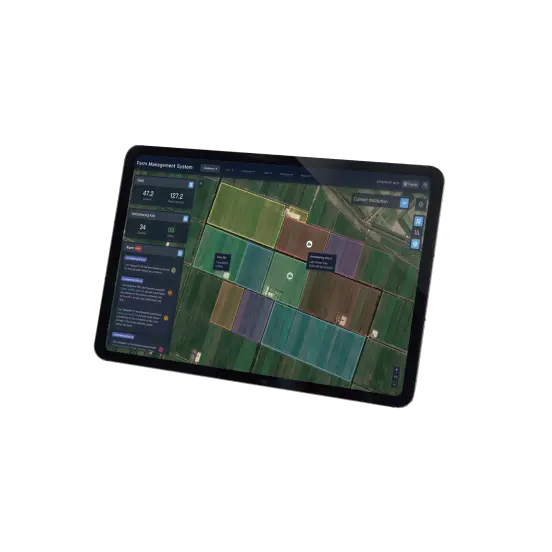

FieldFusion Farm Management System

Sveaverken N20

Fixed High Power GNSS Station

Sveaverken N10 CORS System

Sveaverken V1 Base Station

Sveaverken Thor

Sveaverken Alva

Sveaverken Blix

SveaMow App

- Herd Management

- Precision Farming

- Lawn Care

- Commercial Cleaning

Sveaverken Nimbo X

Sveaverken Glide Flo

Sveaverken FeedLogger

Sveaverken Nimbo

Sveaverken MooCollar Bree

Sveaverken Brush

Sveaverken F200 Max Auto Steer System

Sveaverken F200 Auto Steer System

Sveaverken F100 Auto Steer System

Sveaverken Thor

Sveaverken Alva

Sveaverken Blix